Business Expansion

737 Rate Readiness Facility Optimization

Overview

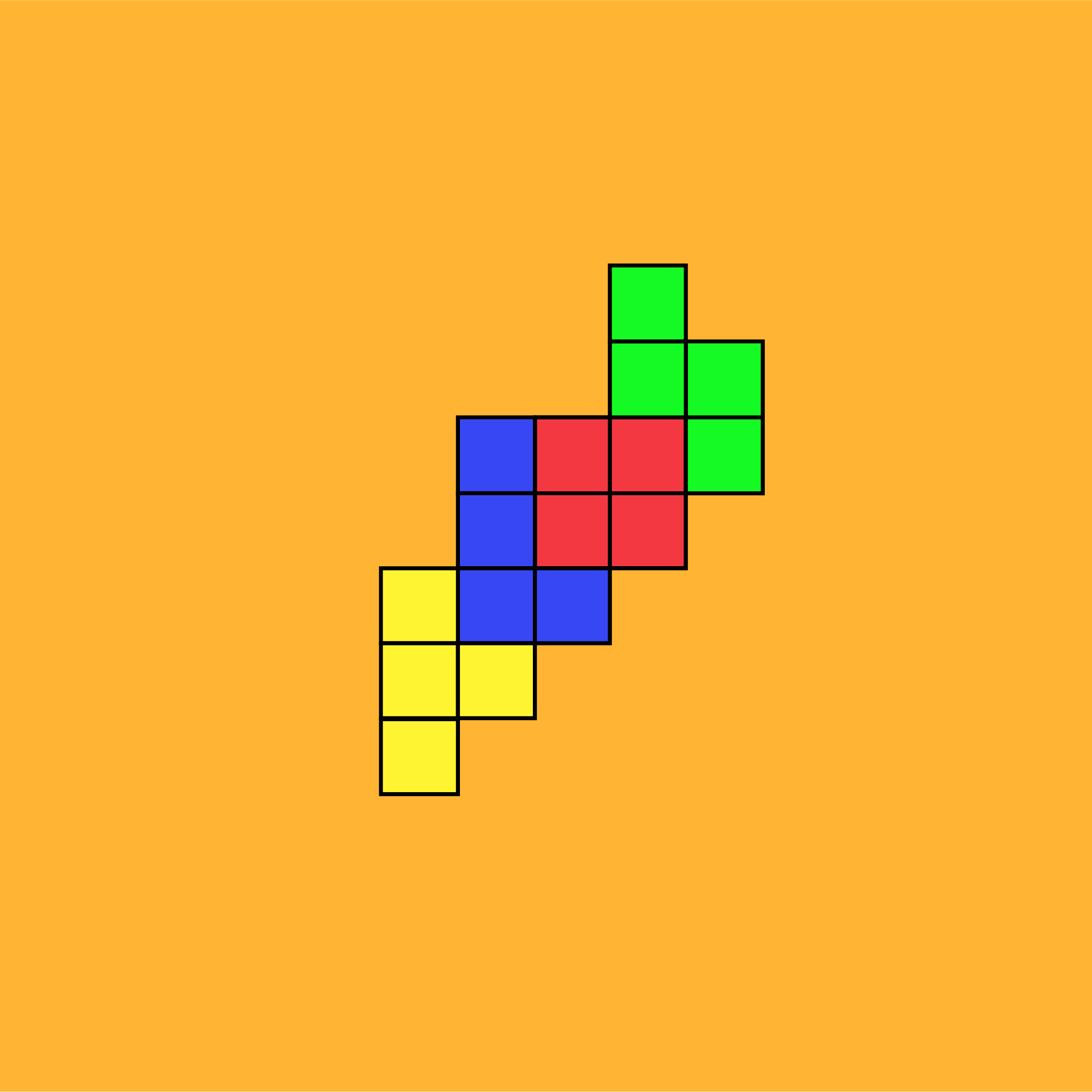

Early in my career at Boeing, I led a $17M facility transformation initiative to support a major production ramp-up: increasing throughput by 20 additional 737 aircraft per month. The effort reconfigured 55 manufacturing departments across 900,000 square feet—without pausing live operations. Like a strategic game of Tetris, every move required careful coordination, fitting disparate production elements together seamlessly to unlock space, efficiency, and flow.

Role & Responsibilities

Directed facility strategy and implementation across 55 production shops

Partnered with 30+ product lines to collect rate, space, and resource requirements

Designed a scalable layout strategy that expanded the 737-program footprint

Maintained continuous operations through phased planning and risk mitigation

Concept and Initiation

Discovery & Initiation

Our industrial engineering analysis confirmed that the current facility layout couldn’t sustain the projected production rate. Shops were boxed in—physically and operationally. I partnered with cross-functional leaders to define needs and constraints, then built a macro-level plan to optimize shop locations, open up flow, and reclaim capacity for expansion.

Planning

Planning & Design Development

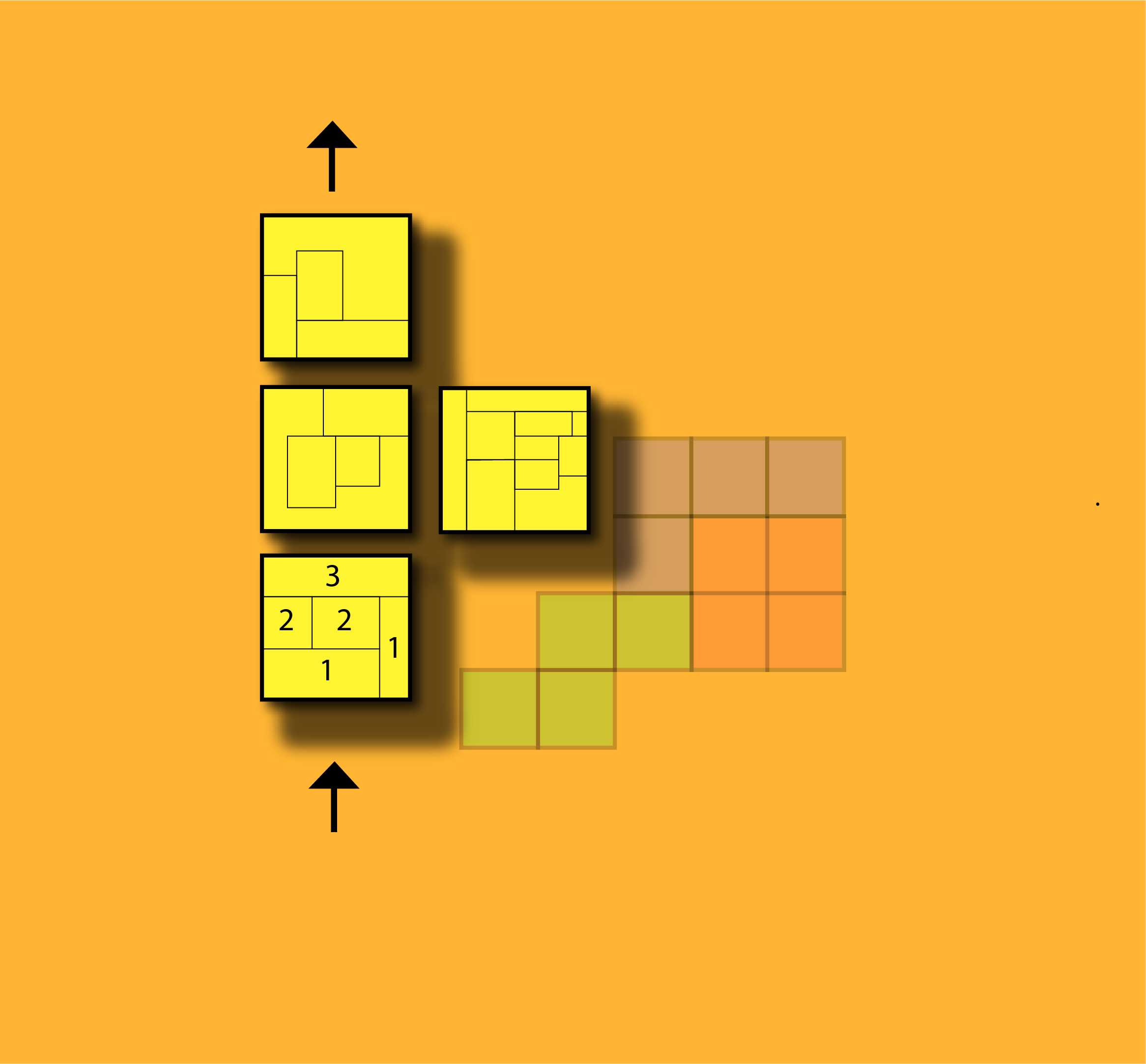

Once approved, I led layout planning sessions with dozens of stakeholders to document:

Workflow dependencies

Shared resource utilization

Equipment and utility needs

Safety, clearance, and egress requirements

I created phased move plans that aligned with engineering changes and production demands, ensuring each new “piece” of the layout would fit into place without creating operational gaps.

Execution and Monitoring

Execution & Iteration

Challenge 1: Shifting rate forecasts and overlapping engineering changes

Resolution: Embedded risk reviews into planning forums and proactively adapted layouts to reflect change orders and evolving requirements

Challenge 2: Limited capacity from shop leaders for ongoing planning

Resolution: Developed focused, time-boxed working sessions and used visual design reviews to accelerate feedback and approvals

Challenge 3: Live production couldn’t pause for reconfiguration

Resolution: Built a phased move strategy with targeted production stoppages, allowing critical work to continue while spaces were reconfigured in sequence

Close

Closeout & Impact

The project was delivered:

On time and within the $17M budget

With minimal post-move adjustments

And with a layout capable of sustaining future production targets

Beyond the tangible results, this experience shaped my operational leadership style: adaptive, systems-driven, and grounded in collaboration. What started as a layout challenge became a career milestone—solidifying my passion for orchestrating large-scale change across people, process, and space.